Foam Die Cut Machine

Foam Die Cut Machine Specification

- Installation Guideline

- Floor Mounted, Follow manufacturer guide

- Coating Type

- Powder Coated

- Surface Treatment

- Coated Surface

- Size

- Standard / Custom Sizes

- Feature

- High precision, Durable structure

- Thermal Conductivity

- <0.045 W/mK

- Layer

- Single Layer

- Density

- Gram per cubic centimeter(g/cm3)

- Product Type

- Foam Die Cut Machine

- Material

- Mild Steel

- Rated Voltage

- 220V

- Tensile Strength

- Strong

- Width

- 900 mm

- Thickness

- 5 mm to 50 mm

- Application

- Industrial Foam Die Cutting

- Breakdown Voltage

- High

- Heat Conductivity

- Low

- Color

- Blue & Grey

- Max Withstanding Temperature

- Up to 80C

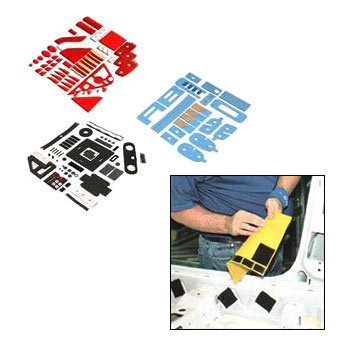

About Foam Die Cut Machine

Experience of many successful years enables us in manufacturing, exporting and supplying high quality Foam Die Cut Machines. These machines are manufactured using premium grade components with the aid of sophisticated technology under the proper direction of our experts. The offered machines are suitable for foam forming, cutting and shaping applications and are demanded in various industries. These Foam Die Cut Machines are extensively treasured all over the globe owing to their high efficiency.

Features:

-

Precisely engineered

-

Trouble-free functionality

-

Less maintenance

-

Long service life

High-Precision Industrial Foam Cutting

Specifically crafted for industrial foam die cutting, this machine combines precision engineering with robust construction. Its advanced coated surface, strong tensile strength, and durable powder-coated finish ensure reliable operation and superior cutting accuracy, even during extended use. Suitable for demanding environments, it delivers both efficiency and high-quality results.

User-Centric Design with Safety in Mind

Installed by floor mounting and guided by comprehensive manufacturer instructions, the foam die cut machine provides stability, safety, and ease of integration into various production spaces. Its high breakdown voltage and low thermal conductivity help maintain the safety of operators during high-volume applications.

Customizable for Diverse Applications

Offered in standard and custom sizes, the machine adapts to various industrial requirements. It is ideal for sectors requiring precise foam components, such as packaging, automotive, and insulation. Flexible and scalable, it serves exporters, manufacturers, service providers, and suppliers throughout India.

FAQs of Foam Die Cut Machine:

Q: How is the Foam Die Cut Machine installed for optimal performance?

A: The machine is installed using a floor-mounted setup and should be positioned on a stable, level surface. Always follow the detailed installation guideline provided by the manufacturer to ensure safe and efficient operation.Q: What types and thicknesses of foam can be processed with this machine?

A: This machine is capable of handling foam materials with thickness ranging from 5 mm up to 50 mm and widths up to 900 mm, making it suitable for a variety of industrial cutting applications.Q: When should maintenance be carried out on the Foam Die Cut Machine?

A: Regular maintenance should be scheduled according to the manufacturers recommendations, including routine inspection of the coated surfaces and moving parts to maintain high-precision performance and long service life.Q: Where is this machine most effectively used?

A: The Foam Die Cut Machine is best suited for industrial environments, such as manufacturing plants dealing with foam processing for packaging, automotive, or construction industries.Q: What is the process for cutting foam using this machine?

A: Foam sheets are placed on the die cutting surface, and the machine delivers precise cuts with its strong tensile force and coated die, achieving a clean and consistent finish each cycle.Q: How does the low heat conductivity feature benefit users?

A: Low thermal conductivity (<0.045 W/mK) ensures minimal heat transfer during operation, enhancing operator safety and preventing damage to both the foam material and the machines components.Q: What are the key benefits of selecting this foam die cut machine for industrial use?

A: Users benefit from its durable structure, high precision cutting, adjustable sizing options, strong withstanding temperature (up to 80C), and user-friendly installationmaking it a cost-effective and efficient choice for continuous industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

KUBHERA INSULATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |